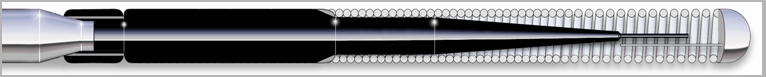

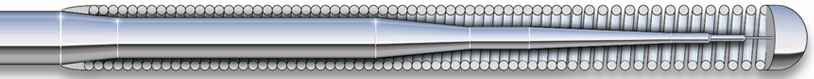

Guidewire core

Editor-In-Chief: C. Michael Gibson, M.S., M.D. [1]

Overview

The core of a coronary guidewire determines many of the performance characteristics of the device. The core of a coronary guidewire is usually ground to a taper towards the end and this is where the tip attaches to the core. If guidewire core starts tapering more towards the tip, the coronary guidewire as a whole becomes more rigid, steerable and torquable. The opposite happens when the core other coronary guidewire tapers more proximally allowing for a longer tip and a more flexible tip. The core may be either continuous or joined. If the core is joined then it is more likely to bend or prolapse when the guidewire is advanced.

Guidewire Core Composition

The guidewire core can be composed of either nitinol, stainless steel or a similar metal.

Nitinol Guidewire Cores

Advantages Of A Nitinol Core

- Super-elastic alloy designed for kink resistance

- Excellent flexibility and steering

- Probably more durable in nature

- Better trackability

- Reduced prolapse

Disadvantages Of A Nitinol Core

- A nitinol guidewire may be less torquable

- A nitinol guidewire core may store torque without necessarily transmitting the torque to the tip

- Wires with single nitinol cores sometimes "wind up" and store the torque

Clinical Scenarios In Which A Nitinol Core May Be Useful

- As a result of their flexibility and durability, coronary guidewires with a nitinol core are more likely to enter a retroflexed circumflex coronary artery.

Stainless Steel Guidewire Cores

Stainless steel was the original core material used in coronary guidewired.

ADVANTAGES – STAINLESS STEEL=

Gives more pushability, torquability, and good shapeability in “core-to-tip” wires. Good support, push force and torque

DISADVANTAGES – STAINLESS STEEL

- Tendency to kink

- Less flexible than newer core materials

OTHER MATERIAL USED IN THE CORE

High tensile strength stainless steel

- More durable than regular stainless steel

- Retains shape more

- Improved flexibility

- Improved steering and tracking